Material Testing

Microstructures/Metallography

Microstructures/Metallography

Microstructures/Metallography

We have metallographic capabilities to evaluate essentially all metallic materials including welds and plating/coating. We also evaluate for inclusion content and grain size. Our metallography department is supported by a variety of sectioning, grinding and mounting equipment.

Hardness Measurement

Microstructures/Metallography

Microstructures/Metallography

Rockwell (including superficial) hardness and microhardness (Vickers and Knoop). Hardness conversion per ASTM E140.

Chemical Analysis

Microstructures/Metallography

Chemical Analysis

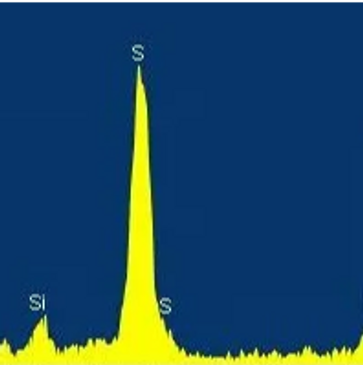

Our chemical analysis evaluation services include OES, ICP, XRF and SEM/EDS.

Tensile Testing

Coating/Plating Evaluation

Chemical Analysis

Tensile testing capabilities range from 10,000 lb to 100,00 lb. A 200,000 lb machine is available for special projects. We can machine round and flat tensile specimens and can test actual parts/assemblies.

Coating/Plating Evaluation

Coating/Plating Evaluation

Coating/Plating Evaluation

We evaluate a variety of plating and coating systems using metallography and the SEM. We also document/measure surface defects and damage.

Corrosion

Coating/Plating Evaluation

Coating/Plating Evaluation

Evaluation of corrosion resistance (salt spray) and analysis of corroded parts via failure analysis.

Evaluation of Welds

Evaluation of Welds

Evaluation of Welds

Weld cross-sectioning, measurement, etching and photographic documentation. Microhardness traverses. Weld failure analysis.

SEM/EDS

Evaluation of Welds

Evaluation of Welds

Scanning Electron Microscopy (SEM) of a wide variety of fracture surfaces and small samples. Supported by EDS chemical analysis.

FTIR

Evaluation of Welds

FTIR

FTIR evaluations of plastics, rubbers, grease/oil and most non-metallic materials. Library of over 200,00 known materials for comparison and identification.